Part 3: Practical Guide

PART C Practical Guide

SECTION C.1, Foundation

General

The function of the foundation is carry the house and its imposed loads (vertical forces) and to transfer horizontal forces (wind, positive and negative) to the underground. The walls of a foam concrete house form a stable structure, that in combination with a floating raft foundation forms an integral box type structure.

A raft foundation forms a strong, flat floor and provides a stable base for the walls.

A raft foundation is suitable for most locations including those with poor load-baring soil. To be complete, also other foundation options are included.

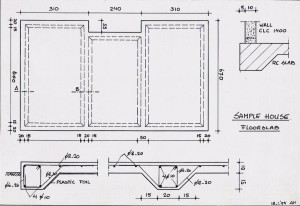

C.1.1 Floating raft foundation

A floating raft foundation is in principle a flat, reinforced dense concrete or foam concrete slab, preferably slightly larger than the wall structure. This oversize of say 200mm (100mm on all sides) provides a ledge on which the external formwork panels can be placed. The edges of the floor slab are dug in to form a beam structure along the edges of the slab. Also thickened reinforced areas might be required under the internal walls to strengthen and stiffen the slab according to engineer’s specification.

A steel profile frame is often used as a mould for the raft. It is placed and fixed in position on the top soil and the thickened areas (edges and beams) are excavated to the profile of the underside of the slab. After these ground works, a damp-proof LDPE membrane is placed in the excavation to separate the concrete from the soil. Next step is to place the steel reinforcement bars or fabric and provisions for the utilities. Rebar chairs and spacers are used to ensure sufficient cover to the steel bars.

After all this the floor slab is cast, with dense concrete or with foam concrete. For the screeding of the floor, the steel edge moulds can act as screed guides. A screed vibrator is fixed to the middle of the screed. After screeding of the floor, the starter bars (continuation bars) are placed in the floorslab. Starter bars are as a rule, in particular with 100mm walls, placed at the centre of the walls to anchor the walls to the slab, according to Engineer’s specification.

The surface of the wet concrete can be screed off with a concrete bull float until a very smooth surface is achieved. Alternatively, once the concrete is set sufficiently, a power float can be used to make a smooth finish to the surface. With both methods, bull float or power float, a very smooth surface is reached that requires no further finishes to the floor.

It is recommended to finish the oversize part of the slab outside the walls with a mortar finish sloping to the edge. This will prevent water collection on the slab and possible seepage into the walls. This is done before completion of the house.

Reinforced concrete raft with starter bars

Reinforced concrete raft with starter bars

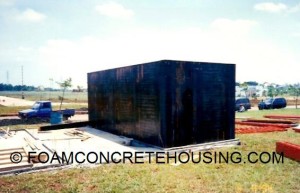

Example of reinforced concrete raft foundation

Example of reinforced concrete raft foundation

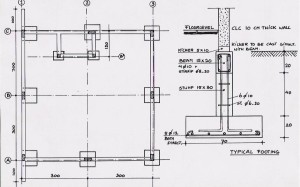

C.1.2 Foundation with footing, pads

Footings or pads are used to carry concentrated loads, whereby the pads are rested on a level with sufficient load-bearing capacity. The dimensions of the pads are related to total load and soil conditions.

Pads can also be applied in case of insufficient load-bearing capacity of the top layer, in situations where a proper load-bearing soil layer is found not so deep, say up to 1.5 meter deep. On the corners of the walls footings are made with concrete stumps which are connected with each other by concrete beams. (See drawing).

The FC walls are placed directly on the beams, and the floor is filled in later.

It is also possible to cast the floor slab directly on the beam structure, so that the walls are cast on top of the slab.

C.1.3 Strip foundation

Strip foundation consists of a continuous reinforced concrete slab under all the walls. On top of the slab small walls of brickwork or concrete are placed to the underside of the floor slab. On top of the floor slab the walls are positioned.

Care must be taken to anchor the FC walls to the foundation by way of starter bars or, in the case of brickwork masonry anchors are used.

A strip foundation is used where there is a good load-bearing soil not far under the surface, where the top soil does have insufficient load bearing capacity.

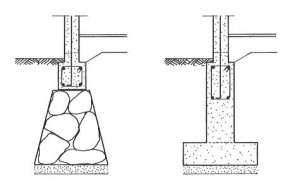

Strip foundation with river stones (left) and with reinforced concrete strip

Strip foundation with river stones (left) and with reinforced concrete strip

Strip foundation with river stones, Sri Lanka

Strip foundation with river stones, Sri Lanka

C.1.4 Piling foundation

In locations where a suitable load-bearing soil is deeper than say 2 meters, a piling system might be necessary.

In general it can be said that in almost all cases and locations a concrete raft foundation will provide a sufficient stable foundation for single and double storey FC houses.

It should be noted though that the final decision about the foundation system is the responsibility of the project’s structural Engineer.

SECTION C.2, The Walls

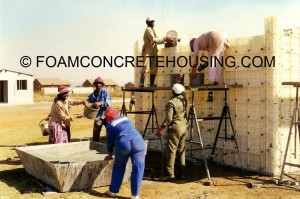

Mould ready, casting in progress

Mould ready, casting in progress

C.2.1 Formwork general remarks

A formwork system for walls is an industrial production method and is often used in a daily cycle. Handling the panels must be done as efficiently as possible. This means that stripping must ideally be in the same sequence as the setting up of the moulds for the next house. After stripping, the panels must be cleaned, checked, transported and treated with releasing agent and placed as close as possible to the place where they will be installed on the next foundation. A help is numbering the panels in the sequence of installation. A quality formwork system requires a substantial investment, so proper handling and maintenance are vital to get maximum usage of the formwork system.

C.2.2 Guidelines for selecting a type of formwork

As mentioned before, there are several types of formwork.

Apart from the height of the investment in formwork, there are a number of other considerations that are important in deciding which type of formwork is the most suitable. Those factors are:

The planned number of usages of the formwork.

Plastic formwork is the cheapest, it allows only up to 100 repetitions. This means that the actual cost for formwork per house is the total cost of the mould divided by 100. For a small, singular project this might be the cheapest option. Please note that plastic formwork has no value after use.

Aluminium and steel frame formwork is more expensive, but can be used (with proper handling) up to 1000 or even more times. Cost of the mould can be divided by 1000 which works out to be cheaper than the plastic mould.

For a large project or a number of subsequent projects, the investment in aluminium or steel framed formwork would be the logical choice.

The weight of the mould.

The mould has to be handled and transported daily. It is clear that the lighter mould would be preferable to a heavier one, saving labour and speeding up the work. Plastic is the lightest, aluminium and ply is lighter than a steel and plywood mould. A full steel mould would be the heaviest.

Setting up and stripping of the mould.

Each formwork system has its own special way for setting up and stripping. Some systems require more, others less labour. Most types of formwork come in storey high panels and require few tie-bars to connect the inner and outer panel. Setting up and stripping is fast.

Plastic formwork comes in small panels that first need to be assembled to larger panels that are handled on site with ease. Plastic formwork requires many more tie-bars, so many holes need to be filled.

The number of components vary per system. More small components means more loss and waste and require more spare items.

The strength of the mould

Moulds have to withstand the lateral pressure of concrete during pouring and curing of the foam concrete. The high fluidity of FC causes a hydrostatic pressure on the formwork during and direct after casting.

The heat of the hydration of the concrete will cause the air bubbles in the foam concrete to expand, causing a lateral pressure on the formwork that can be higher than the initial hydrostatic pressure. This “hydration” pressure can occur several hours after casting. The use of rapid hardening cement will increase the hydration pressure as it generates higher temperature. The use of fly-ash as replacement for part of the cement will lessen the effect thanks to lower hydration temperature.

A lower density foam concrete will have higher hydration expansion than higher density FC because of the difference in air content.

Almost all quality formwork systems have a strength of at least 60kN/m2 which is sufficient for all FC applications. Care should be taken with formwork systems with lower strength.

Fixings to the mould surface.

A number of items are cast into the wall and require fixing into the mould prior to casting. This means that screws, bolts and or nails need to be fixed to the formwork surface. This must be done with utmost care and precision. It is clear that fixing something to plywood or composite surface panels from the steel and plywood formwork and aluminium and plywood is easier than to steel surface. Careless fixings to plywood will cause the plywood to deteriorate quickly and will make early replacement of the plywood necessary.

Fixings in steel panels must be pre-drilled and the correct type of bolt and nut must be used. A panel with provision for a window or doorframe must always be used for that window or doorframe and in that same position. This means that drilling to that specific panel need to be done only once. This will stretch the life span of the formwork.

Please seek the advice of the formwork supplier.

C.2.3 Guidelines for handling formwork

Handling formwork in the correct way will extend its life substantially and improve the quality of the produced walls. Following is a list of guidelines for the correct handling of formwork.

1.Panel layout drawing

A layout drawing of the house must be made with the formwork panels drawn in it and individually numbered., as much as possible in the correct sequence of setting up of the mould. The panels must have this numbering as well. In case of simultaneously production of similar houses, each mould must be marked as a set as well.

2.List of components

Together with the layout drawing a complete list of components must be made. This will list out all large components (panels), small components, tools and other parts belonging to the formwork set.

3.The floor-slab

The surface of the floor-slab must be flat and clean. It is advisable to mark the position of the walls with a marker line, the formwork panels will follow these lines.

4.Preparing the mould

The mould must be prepared complete with numbering and fixings. Any damage due to cutting or fixing must be repaired and treated with a conserving paint to prevent rotting (plywood) or corrosion (steel).

5.Releasing agent

Panels need to be cleaned properly of all FC remnants after each casting. Some companies provide a high pressure water pump to facilitate cleaning.

The area in contact with FC must be treated with a release agent. This release agent will protect the panel surface and improve the surface of the cast wall. Release agent must be sprayed on with a hand held pump in a very thin layer that does not run, but adheres to the mould surface.

C.2.4 Kicker

Unless the floor is extremely flat and level, some leakage at the bottom of the mould during casting will occur. This can be prevented by making a kicker, prior to casting and the setting up of the mould.

A kicker is the base of the wall of a few centimetres high. Working with a kicker requires precise measurement to allow the wall panels to fit. If there is sufficient time available before casting, a few buckets with mortar can be cast into the wall mould to form a thin layer of mortar that seals the mould during casting.

C.2.5 Setting up of the Mould

As a rule, the inside panels are erected first, starting with corners to get instant stability. This is the more important when moulds are set up in windy conditions. Against these inside panels, the doorframes and window frames are mounted, electrical boxes and piping can be fixed and block-outs for roof beams can be placed. Reinforcement bars are fixed together as per Engineer’s requirements and kept (in most cases) in the middle of the wall with plastic spacers.

Once all this have been done, the external moulds can be placed, and the formwork can be completed including the tie-bars. Alignment is done with walers and braces (push-pull props) as available for the used formwork system.

Inner mould is placed first. Please note kicker on the left.

Inner mould is placed first. Please note kicker on the left.

C.2.6 Preparation for Casting

Scaffolding of any type (separate or integral part of the formwork) must be placed along the walls so that casting can be done from each part.

Most system formwork suppliers, can supply scaffold brackets to form a working platform at wall height level.

The complete mould must be checked thoroughly before casting, as corrections are nearly impossible once casting has commenced. This checking concerns mainly the tightness of mould, the alignment, the tightening of the tie bars, the concrete cover on reinforcement bars and the proper fixing of cast-in items.

C.2.7 Casting

Casting into the moulds can be done manually with buckets, with a mortar- or concrete pump or with a small crane with a skip. Funnels should be used on top of the formwork to ensure that the concrete flows into the mould and does not spill over and so dirties the moulds. Filling the moulds must be done in such a way that all the walls are filled more or less at the same speed. Foam concrete is very liquid and flows very well within the mould. Care should be taken to limit the horizontal flow of the FC as too far a horizontal flow might lead to segregation of the FC. Care should be taken to use a hose to the funnel to limit the free fall of the FC in the mould to about 1.5m.

Important is the speed of casting, the faster the mould is filled, the higher will be the concrete pressure on the walls.

Directly after casting it is recommended to hose down the formwork to clean the mould of spilled FC. This will contribute to preserve the formwork mould.

Concrete truck mixer with pump

Concrete truck mixer with pump

C.2.8 Casting manually

If no crane or suitable pump is available, the moulds can be filled manually with buckets. A large bin is placed near the house in which the foam concrete is delivered. Buckets are filled in this bin and hoisted to the top of the walls and cast into the walls. Also a small lift can be used to lift up the filled buckets.

Manual casting by filling and hoisting buckets

Manual casting by filling and hoisting buckets

C.2.9 Stripping of the Mould

Formwork tie bars and the formwork panels must be stripped as soon as the curing of the concrete allows this. FC is in fact a cement rich mortar and shrinkage to a minor degree will occur. Most of the shrinkage will occur during the first hours of setting. Please note that all provisions for windows, doorframes, piping etc that are bolted through the formwork panel, must be removed before stripping can commence.

Most difficult to strip are the formwork panels that are locked in, say inside a toilet or small bathroom. Often the formwork supplier can provide special strip panels to overcome this problem. It is also advisable to use a number of narrow panels for such as wall; better are 3 panels of 300mm than 1 panel of 900mm.

The moulds must be cleaned immediately after stripping and treated with a releasing agent before setting up the mould again to produce the next house. Some moulds can be cleaned with a high pressure water jet in accordance with the supplier’s instructions.

It is important to always store the panels on a flat surface with thin timber strips between panels so that the panels are not damaged nor subject to warping. This is also the preferred way of transport to and from site.

SECTION C.3, Foam Concrete

C.3.1 Density and Dimensions

Foam concrete can be produced in several densities, each with its own properties. A lower density has less strength, but higher thermal insulation. A higher density combines higher strength with lower thermal insulation. This choice in densities, together with the option to apply several wall thicknesses, makes it possible to apply FC for any type of house under all possible conditions: moderate or tropical climate, in earthquake region or in cyclonic areas.

On average, a wall thickness of 100mm will suffice in most cases. However in exceptional circumstances 150mm or even 200mm might be a better choice.

The project’s structural engineer will indicate the required wall thickness that is needed in order to comply with local Rules and Regulations.

C.3.2 Materials

Sand

Sand must have a high silicate content of about 90%, be free of pollution and have a good variation of grain size. A rounded grain shape (river sand) is preferable over sand from crushed stone as it will have more sharp edges that will break down (part of) the foam bubbles.

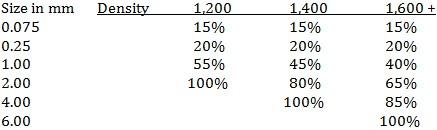

The amount of fines (small particles of not more than 0.075mm) must be minimum15%. Please note that particles smaller than 0.005mm have a negative influence on the quality and properties of the FC.

Maximum grain size is 2mm for density of 1,200kg/m3, 4mm for 1,400 and 6mm for 1,600kg/m3 or higher density.

A sieve test must be conducted, on the basis of the sieve test results the foam supplier can advise on the best composition for the FC.

As an example, following sand gradation is suitable for FC.

Sea sand is suitable when thoroughly washed to remove chlorides etc.

Cement

The cement to use is Ordinary Portland Cement with a minimum quality of 42.5MPa (General purpose PC), or Type I PC (According to ASTM C150) Other types of Portland cement can be used depending on existing conditions. Available are rapid hardening cement and cement with higher sulphate resistance for concrete in contact with alkaline soil or water.

Water Cement Ratio

For FC, the water-cement ratio is normally 0.5, meaning that for every kilo of cement about 0.5 litre of water is used in the FC mix. For the hydration of the cement, a ratio of 0.25 is required. The extra water is for workability and will gradually dry out of the concrete. The ratio of 0.5 includes the water that is needed for the production of the foam.

Fly ash

Fly ash can replace part of the cement. Fly ash should have a high fineness, low carbon content and a good reactivity. When fly ash is available, it is recommended to contact foaming agent supplier for advice for application and composition of FC.

Sustainability options

Part of cement might be replaced by:

Pozzolanas, rice husks ash, incorporated in the production of cement;

Magnesium Oxide Cement (eco cement) as it requires only about 40% of the energy required for the production of PC.

Admixtures

A few types of admixtures are available such as water reducers, retarders and accelerators.

Application of admixtures should be decided by CLC expert, or supplier of foaming agent.

Water

Water must be clean, drinking water (potable), and at the time of mixing preferably not warmer than more than 25 degrees Celcius, this is in particular important for foam production where the foaming agent is diluted in water.

Foaming agent

Main requirement of foam is that is must remain stable and does not collapse during transport, pumping, placement and curing. The presence of millions of air bubbles highly increases the workability of the FC.

Foaming agents that are used to produce a pre-formed foam are either protein based foaming or synthetic.

Air entraining agents are also used to form air in mortar mixes, but their effect is limited to a few percent of air content, and fall outside the range of foam concrete.

Protein based foaming agents are used frequently as they provide a stable and strong foam. This type of foaming agent has been used for several decades. It can be produced in a wide range of densities, applicable for void filling and insulation, architectural features, blocks, panels and for structural purposes.

In recent years, the synthetic foaming agents have improved significantly and their performance is similar to protein foaming agents.

A recent development is enzyme based foaming agents.

Polypropylene Fibres

Polypropylene fibres are added to the mix after the sand, cement and water are mixed thoroughly and before the foam is added. Typical quantity is 0.9kg per m3 of CLC. Fibres come in bags of 0.9 kg that can be introduced directly into the mortar mix, the bags will disintegrate during mixing.

C.3.3 Cellular Structure

Cellular Lightweight Concrete (also known as Foam Concrete) is characterized by porosity which is uniformly distributed throughout the mixture. The porosity consists mainly of macro-pores, almost spherical air bubbles with a diameter of 0.1mm – 2mm.

With pre-formed foaming agents, the air bubbles are formed in a shaving- creamlike foam and then added to the sand-cement-water mortar mix.

Air bubbles have a number of advantages:

-Reduced material usage of the concrete;

-Improved thermal insulation properties of the FC, be it at reduced compressive strength;

-Improved workability;

-Decreased segregation, bleeding and permeability.

C.3.4 Mixing the CLC

Pre-formed foaming agent

It is necessary to produce CLC of a constant composition and quality. Materials need to be weighed or measured for each mixer load. Sand, cement and water are mixed first to a consistent mix before the foam is added. The pre-formed foam must be placed as far back as possible in the mixing drum.

The mixing has to be continued until the foam is taken up completely. Adding and mixing of preformed foam might take a few minutes. It is essential to mix as long as necessary to get a homogeneous and highly fluid cellular concrete of consistent quality.

When a batching plant is supplying the FC, the fibres and the pre-formed foam can be added at the plant. Exception is when the site is more than 30 minutes drive away and in particular when the roads are not in good condition. In that case foam must be added on site. Please note that when foam is added on site, the truck mixer will transport only the mortar mixture which is significantly less than the capacity of the drum. (FC of 1,400kg/m3 contains 37% air, so only 63% material is transported to site. Only once the foam is added, the full capacity of the drum is reached.

When polypropylene fibres are used, the fibres are added after the sand-cement-water mixture is mixed homogeneously. When the fibres are distributed evenly through the mix, the foam can be added.

Before mixing, in particular if mixing takes place on site, the sand must be sieved to take out larger stones. Stones larger than the indicated grain size will cause problems in the wall and might block the pump in case concrete is pumped. Sieving after mixing is impossible if polypropylene fibres are used as they will block the sieve.

C.3.5 Remarks

There are a few measures that can be taken to reduce cost and foam concrete wastage on site:

- When FC is delivered from a batching plant, try to order every delivery in full loads. It is handy to have special moulds ready on site, say for blocks, concrete panels and decorative items, that can be cast with excess FC. Blocks can always be used as infill, as partition walls, for extensions etc. Panels can be used for garden partitions, garden sheds etc.

- When a batching plant is supplying the FC, it is advisable to have a small mixer on site with stock of sand and cement, so that when there is a small shortage, this small quantity can be produced on site and does not require a mixer truck to make a trip nearly empty at often high costs.

- The ordered quantity must include an extra percentage for wastage on site. Ordering a small quantity to complete the pouring is expensive.

Equipment needs to be cleaned directly after use: All equipment must be hosed down immediately after use with plenty of water. This is in particular important for the hoses of concrete or mortar pumps. Material left in the hose will set quite quickly and ruin the hose. Clean water must be run through the foam generator after production of foam to clean the generator and hoses.

SECTION C.4, The Roof

C.4.1 Roof Structure

Provisions for the roof are incorporated in the walls. In general these provisions would be blockages where the beams would be positioned as well as an anchoring system for the beams In case of timber beams, the parts in connection with the walls must be treated with a suitable preservative paint before the beams are placed and anchored.

In case of metal beams, girders or trusses the appropriate block-outs and anchor bolts would have been incorporated in the walls, facilitating easy installation of the roof structure.

C.4.2 Roof panels

The cheapest solution will be to use corrugated steel panels to close the roof. Together with capping and flashing a waterproof roof is made.

Long lasting metal roof panels are available including cyclone resistant panels. These type of panels require special fixing anchors and washers, and stronger walls anchors, all to engineer’s specification.

C.4.3 Other roof Solutions

Any other roof system, including roof tiles, can be applied. The anchoring system for the roof to the walls can be incorporated into the walls.

SECTION C.5, Finishing the House

Finishing the house can be basic or elaborate. The finishing is basically the same as the finishing of any kind of house with a number of remarks. The roof should be installed and completed as soon as possible to allow the walls to harden normally and to prevent excessive water in floor and walls. If the floor is smoothened with a bull float or power float, no further finish to the floor is required. If so required the smooth floor is ready to receive carpet or vinyl finish. Area’s that are to be tiled with ceramic tiles should not be too smooth to improve bonding.

Walls, depending on the type and condition of the formwork mould, normally come quite smooth out of the mould. After filling of the tie bar holes and touching up of imperfections, the walls can be painted, treated with decorative plaster or tiled. Special cement based glues are available to install the wall tiles. It is recommended that the walls are dried out and hardened for a few weeks after casting before tile finish is applied.

The cellular nature of FC is very suitable for using plug and screw type fixing for installing items to the walls – timber strips, mouldings, small cabinets, lighting fixtures, decorative items etc. – can be installed without problem.

In case of additional partition walls are extensions, wall anchors can be fixed in the FC.

SECTION C.6, Technical Installations

A distinction has to be made for the installation inside the house and those outside the house including connection to main water and electricity supplies and waste water discharge.

Piping, conduits, power point and switch boxes inside the house are cast in the floor and in the walls. The installation of wiring, switches, sockets, taps, sanitary wares, waste water discharge etc. can take place after the walls are completed and the house is waterproof.

Connecting the services to the municipal mains and sewer system requires attention as these connections can work out to be quite costly.

Sometimes water is pumped up near the house and waste water is directed to a septic tank with overflow. Also these costs have to be included.

SECTION C.7, Project Requirements

C.7.1 Planning

Before the construction of a project can start, a very thorough and detailed preparation is necessary. In general it can be said that a speedy and untroubled construction phase depends to a large extend on the quality of the preparation.

Formwork systems, special equipment and foaming agent and pp fibres have to be selected, purchased and shipped in, taking up a few months at least in most cases. Once the number and types of houses and the total construction time have been established, the type and quantity of formwork can be worked out.

Out of the planned daily construction follows the number of formwork sets.

This in particular for long-running production streams with a fixed housing programme. For projects with different models it is important to calculate the formwork requirement throughout the total production period. In case of more formwork is needed over a small period of time, the adjustment of the production planning might increase formwork efficiency and reduce the overall requirement.

Smaller projects can start with a formwork set for the largest house model, and after completion the mould can be adjusted for a smaller model. In ordering the formwork, this option should be taken into consideration.

Since formwork requires a substantial investment, it is advisable to look into the possibility to stretch the construction time to reduce the formwork quantity. It is important to realise that also a number of spare parts and panels are required. Since application of formwork is essential, the design should take the possibilities of the formwork system into consideration. Difficult or complicated layouts should preferably not be used as it would add much to the cost, and in most cases, would add little to the value and/or usefulness of the house.

For Low Cost Housing, the keywords are SIMPLE and REPETITION.

C.7.2 Daily Production Cycle

As is mentioned before, this FC technology is based on a daily production cycle. This simply means that formwork is used to produce walls every day. In the morning the formwork is stripped, cleaned, transported to the next foundation, set up and filled with foam concrete on the same day. This is the most efficient usage of formwork.

It is applicable for small houses with a simple layout. All the walls of the whole house can produced in one working day.

There are a number of ways to ensure this daily production cycle:

- For smaller projects, houses may be built with less formwork to produce part of the walls each day.

- Larger houses might need a different production manner. When a complete mould is available for all the walls of the house, the mould can be split into sections so that each day all sections are cast, be it on a different foundation. This way still one full house is built per day.

C.7.3 Cellular Foam Concrete

A vital part is the production and casting of the FC for the project. Once the daily production programme has been established, the total volume of FC can be calculated. The FC can be poured only once the moulds are completely set up and ready: this means that the total volume of FC has to be produced, transported and poured in the space of a few hours. Thus the hourly needed volume is known and the required mixing capacity, as well as transport and pumping can be worked out.

For larger volumes, working together with a nearby concrete batching plant might be a good solution. When this is not possible, mixing on site is the obvious choice and the best solution for mixing, transport and casting has to be worked out.

SECTION C.8, Purchase

General remarks

The purchasing of materials and equipment for a project is of vital importance. It is important to maximize the use local materials and building products as this will benefit the local economy and keep costs down. The import of specialized equipment and products must be given a lot of attention as it time consuming. It involves asking for several quotations, production time, often land- and sea transport, special payment conditions, insurance, import license and possibly import duties, levies and documentation. It is often wise to engage a forwarding company to arrange and assist in these matters.

Some companies can supply reconditioned formwork at a reduced cost.

For some projects and locations it is also possible to rent formwork.

C.8.1 Formwork

Once an in-principle decision has been made about the type(s) of formwork, it is time to ask quotations from two or more preferred suppliers. The suppliers would need following information to be able to make a proper quotation:

1. Company and project information, contact person.

2. Layout and elevations of all walls of all types of houses.

3. Types and number of houses, construction planning for each type of house.

4. Delivery time to site for all models or per model.

5. Delivery conditions such as FOB, C&F, CIF etc.

Quotations should at least include:

1. Price for formwork per model and per component.

2. Price for special components such as scaffold brackets and push-pull props.

3. Lead time, shipping time and type of container.

4. List of recommended spare parts

5. List of items such as plywood for panel replacement.

6. Payment conditions

It is certainly worthwhile to work out several option for the execution of the project. The quantity and type of formwork and the usage and routing of it on the project have a marked influence on the cost and result of the project.

C.8.2 Foaming Agents

Foam concrete of densities up to 1,800kg/m3 are produced with pre-formed foam. In general pre-formed foaming agents are protein based or synthetic and have a high stability. Many houses, produced with (protein based) foaming agent are today more than 40 years old in still in excellent shape.

Buying foaming agent also entails tapping into the experience of the supplier, so the choice of supplier in this specialized field is very important. The supplier will advise on the composition of the FC, based on locally available sand and cement. The supplier of foaming agent normally can supply the foam generator.

C.8.3 Equipment for Cellular Concrete

Equipment for the production, transport and casting of FC are foam generators, mixers, truck mixers, flatbed trucks, mortar pumps, cranes and generator sets.

Choosing the necessary equipment can only be done once production method, required volume and density and type of agent is confirmed.

All equipment must be most reliable with back-up for service and spare parts from supplier close by. Break down of a mixer unit means that the whole construction program is reduced or completely stopped which is very costly.

It is advisable to arrange back up of suitable equipment for instance by making rental arrangements prior to construction start.

SECTION C.9, Labour and Cost information

C.9.1 Cost Calculation of Foam Concrete Walls

General Information

The cost of (all the) walls of a house in foam concrete is calculated in a number of steps:

- The cost per m3 of foam concrete is calculated;

- The surface area of walls and formwork is calculated

- Total cost of the walls is calculated.

Currency: All calculations in USD –

Conversion Euro 1.00 = USD 1.10 where applicable.

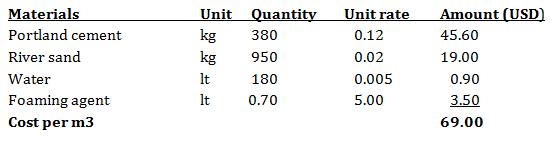

Calculation of cost of 1m3 of foam concrete

1,400kg/m3(oven-dry) density.

(Unit rates are estimated).

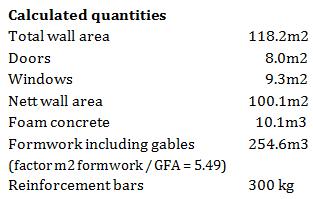

Calculation of walls of a house, model 46.36m2.

Basic information

House model:

-One storey, external dimensions 6.10m x 7.60m

-Living area with open kitchen, two bedrooms, one bathroom.

Conditions:

-Normal conditions, no cyclone or earthquake hazard.

Foundation:

-Floating raft foundation in foam concrete density 1,600kg/m3.

Walls:

-All walls in foam concrete, density 1,400kg/m3.

-All walls are 100mm thick and 2.70m high, gable ends 3.60m.

-Reinforcement of walls to be 3kg/m2 wall.

-Walls do not need plastering.

Currency:

-Calculation in USD, conversion rate from Euro is 1.10

Building speed:

-All walls of one house per working day.

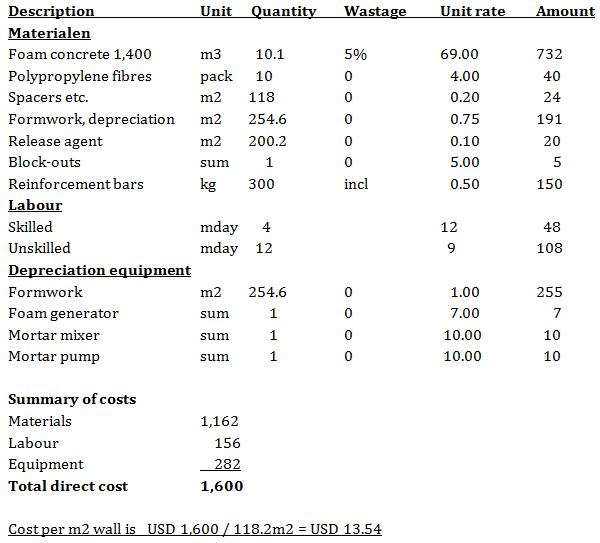

Calculation of cost of walls in USD

Remarks calculation

All rates are used on the basis of best estimate, and will vary per country and location.

Depreciation of formwork ranges from USD 0.35 – USD 1.50, depending on type of formwork, number of houses, repetition and purchase or rental.

Block-outs are used to place and fix doorframes and windows in the formwork mould.

Windows and doorframes can also be installed later in openings that can be made in the walls.

Labour is based on a efficient type of formwork with storey-high panels with aluminium frame. Other types of formwork might require more labour.

Not included are overhead, energy costs, provisions for services and anchors for roof structure.

C.9.2 Equipment

- Foam generator

A foam generator transform a water-foaming agent mixture into a stable foam that is mixed into a sand-cement-water mortar. The foam generator consists of a foaming pipe and a air compressor. Foam generators are availble from many companies, in many capacities and versions. A foam generator needs to be fitted with a timer and/or flow meter, to ensure that each time the correct volume of foam is produced. Almost all foam generators allow the weight of the foam to be controlled.

Prices range from USD 4,000 – USD 16,000. For budget USD 6,000,-

- Mixer

Almost every type of mechanical mixer is suitable, as long as the capacity is at least 600lt per mix. Special foam concrete mixers are available, on skids or on wheels, with electrical or diesel engine.

Prices start at USD 8,500 for a 7.5HP electric engine with 1.15m3 capacity.

Diesel engine mixers start at USD 22,000 for 1.15m3 capacity.

- Pump

Pumps to transport the mortar from mixer into the formwork will cost from USD 8,000 upwards. This is including hose and spare parts.

It is also possible to use manual casting, so strictly speaking a pump might not be required.

- Foam concrete production unit

Combined mixer and foam generator sets are available, often mounted on wheels.

Prices start at about USD 20,000.

- Generator set.

Equipment is ofter powered by 380V, 3-phase electric engines. As this is not always readily available at sites, a power generator might be included.

D5 Creation

D5 Creation